China's electronic technology is developing rapidly, electronic PCBA processing, packaging is showing a new trend of high-precision miniaturization, and the requirements for circuit assembly quality such as SMT chip processing and plug-in processing are getting higher and higher. Specifications. In order to meet the requirements, new inspection technologies are constantly innovated. X-Ray inspection technology is the best among them. It can not only detect invisible solder joints, such as BGA, but also perform qualitative and quantitative analysis on the inspection results. In order to detect faults early.

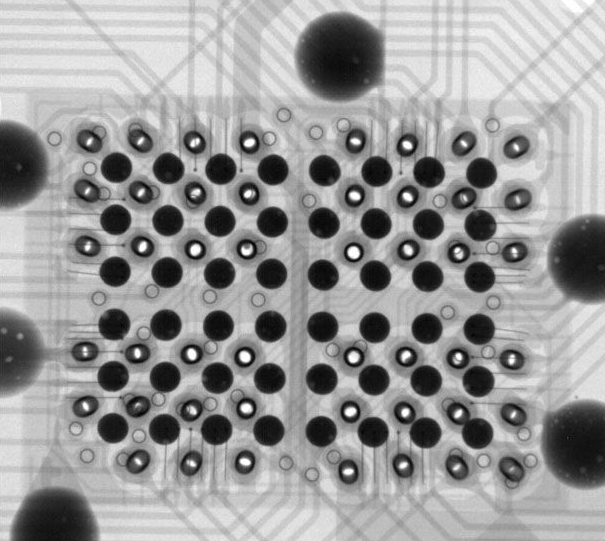

In the field of electronics manufacturing, the common problems are: poor wetting of BGA array devices, internal cracks, voids, continuous tin, low tin, broken parts in complex precision assembly parts, misalignment, hidden originals, PCB open / short, electronics Component failure, etc. These problems, with the help of X-Ray inspection technology, can provide perfect answers to the internal physical structure characterization, defect detection and analysis, and failure analysis of semiconductor packaging devices, and meet the inspection needs of high-end electronic manufacturing technology to help improve manufacturing Process, which greatly improves the yield.

After the BGA device is soldered, its solder joints are all covered by the device body. Therefore, it is not possible to observe and inspect the solder joint quality of all solder joints using traditional visual inspection methods, nor to use automatic optical inspection equipment to judge the appearance of solder joints. . In order to achieve effective inspection, X-ray inspection equipment can be used to inspect the solder joints of BGA devices.

X-Ray imaging

BGA device solder joint defects mainly include solder bridges, solder beads, holes, misalignment, open circuits, missing solder balls, cracks in solder joints, and false soldering. These hidden defects ultimately have an inestimable impact on the life and reliability of electronic equipment.

With the development of new technologies, ultra-high-resolution and intelligent X-ray inspection equipment will not only provide time-saving, labor-saving and reliable guarantee for BGA device assembly, but also play an important role in the failure analysis of electronic products. Troubleshooting efficiency.

National Service Hotline

ELT Technology Co., Ltd. All rights reserved

Address: 3rd Floor, Building B, Building 3, Building 2, Guangshen Road, Chaogang Town, Songgang Town, Bao'an District, Shenzhen, China.

Tel: 0755-29411968

Fax: 0755-27330185

E-mail :elt@elt-usa.com

Website: Http://m.szcyprint.com

Wechat Public Number

Mobile website