Shenzhen Elant Technology Co., Ltd.

Our company will participate in the 7th China Electronic Information Expo in CITE2019, and the booth 9F011 in Shenzhen Convention and Exhibition Center on April 9-11. We invite you to visit and negotiate!

》》》About the Expo

China Electronic Information Expo (CITE) is co-sponsored by the Ministry of Industry and Information Technology and the Shenzhen Municipal People's Government. With the theme of “Innovation-driven development, wisdom and empowerment in the future”, the Expo will focus on the latest development achievements of the new information technology industry, promote the breakthrough of core technologies in the industry, and lead the supply-side reform of the information technology industry.

》》》about us

Shenzhen Elant Technology Co., Ltd. is a national high-tech enterprise integrating R&D, production and sales. The independent products include micro and nano X-ray tubes, X-ray image intensifiers and X-RAY non-destructive inspection instruments. The company specializes in providing tailor-made non-destructive testing solutions for PCBA, SMT assembly, semiconductor devices, lithium batteries, automotive electronics, solar energy, LED packaging, hardware die-casting, connectors, and hubs.

》》》On-site exhibits

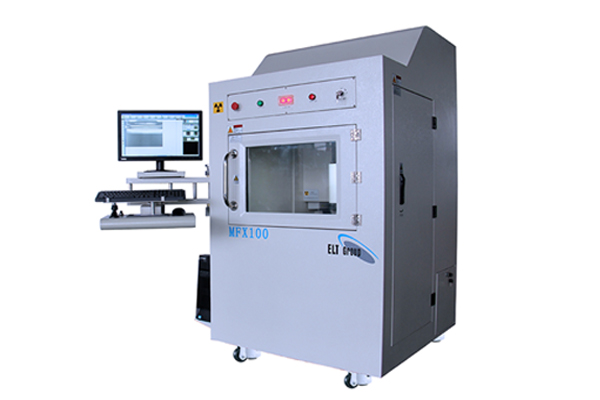

Lithium battery testing X-ray-MFX100 is an off-line automatic detection for cylindrical 18650/26650 lithium batteries. The device adopts PLC control, emits X-rays through the X-ray generator, penetrates the inside of the battery, and the imaging system receives X-ray imaging and photographing, processes the image through relevant software and automatically measures and judges, determines good and defective products, and Pick out the bad products.

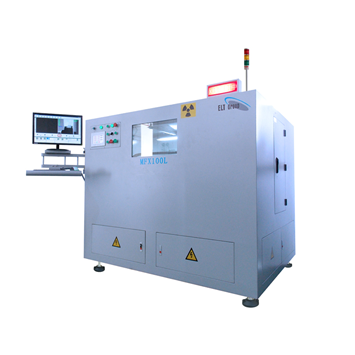

MFX100L uses x-ray inspection software to detect data such as positive and negative winding dimensions, winding deviation, and electromagnetic fastener position deviation. The threshold setting, intelligent shielding of small defects, highlighting large defect intelligent analysis, output Analyze the report, identify good and defective products, and select the defective products. The front and rear ends of the equipment can be docked with the production line.

MFX100LI is applied to the battery industry. It adopts the principle of X-ray transmission and penetrates the inside of the battery. It performs on-line detection and analysis on the internal structure of the cylindrical battery ear and the coverage of the positive and negative electrodes. It automatically detects and determines the negative electrode and shell in the 18650/26650 battery. The condition of the wall (pitch, touch distance, bending state of the ear), is an efficient, professional, high-quality lithium battery testing equipment, automatic determination, data storage and defective product identification, screening and isolation, etc. Automated control of the test process.

MFX100LR is mainly used in the battery industry. It is used for online or offline automatic detection of polymer soft pack batteries. It adopts X-ray transmission principle. Two sets of optical imaging systems collect images online, and automatically detect and correct the anode-anode height difference of the battery through software analysis. Judging and sorting, identifying good and bad products, and selecting and handling the defective products, and the good products are transported through the belt to the next process.

At that time, welcome new and old customers to visit the booth F011 of the Elite Technology booth in Hall 9. For more product information, please call our national service hotline: 400-630-6556 0755-29411968 or visit the official website of m.szcyprint.com

National Service Hotline

ELT Technology Co., Ltd. All rights reserved

Address: 3rd Floor, Building B, Building 3, Building 2, Guangshen Road, Chaogang Town, Songgang Town, Bao'an District, Shenzhen, China.

Tel: 0755-29411968

Fax: 0755-27330185

E-mail :elt@elt-usa.com

Website: Http://m.szcyprint.com

Wechat Public Number

Mobile website