Application of X-ray nondestructive flaw detector in foundry industry

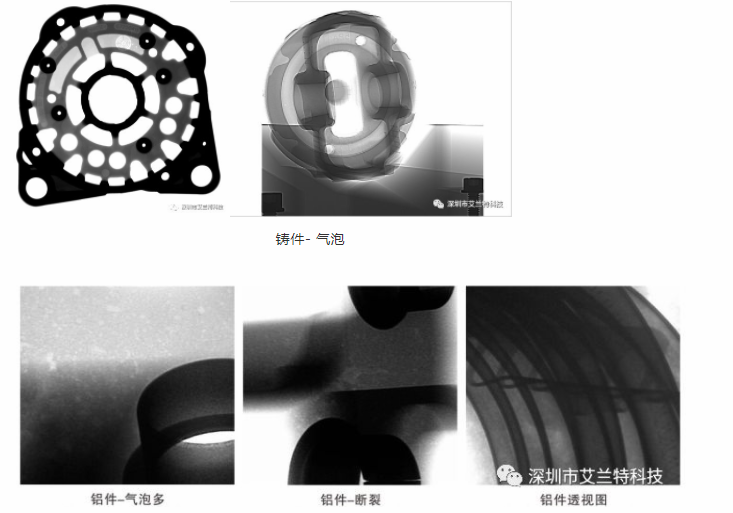

At present, many domestic aluminum alloys, hardware parts, automobile wheels, etc. in the die-casting industry, the internal air holes and internal shrinkage holes in the die casting process affect the main factors of scrapping.

In order to ensure and improve the quality of casting products, meet the requirements of mass production, and better detect the internal conditions of castings, the test results must be timely and accurate. Our company's independent research and development products include micro- and nano-scale X-ray tubes, X-ray image intensifiers and X-RAY non-destructive inspection instruments. By designing data acquisition and monitoring systems for the production process in the inspection equipment, the quality can be traced. All the data of the production process of the product, so as to analyze the cause of the quality problem, point out the direction of rectification, and completely solve the quality problem of the product from the source.

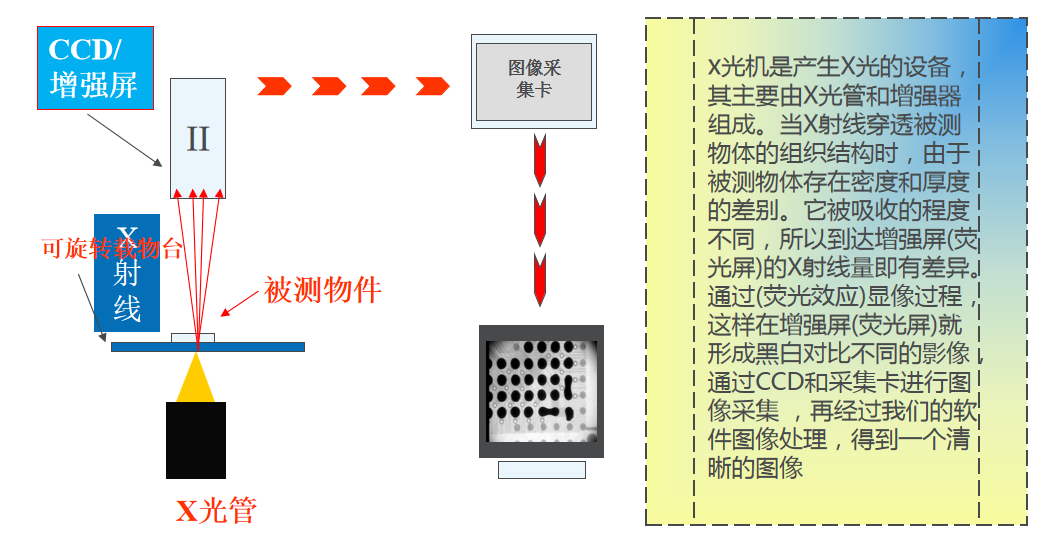

An x-ray machine is a device that produces X-rays, which is mainly composed of an X-ray tube and an enhancer. When the X-ray penetrates the tissue structure of the object to be measured, there is a difference in density and thickness due to the object to be measured. It is absorbed to a different extent, so the amount of X-rays reaching the enhanced screen (fluorescent screen) is different. Through the (fluorescence effect) imaging process, the black and white contrast images are formed on the enhanced screen (fluorescent screen), the image is captured by the CCD and the capture card, and then processed by our software image to obtain a clear image.

X-ray automatic online non-destructive testing equipment uses machine vision technology to improve detection speed and accuracy, provide analysis and judgment on the causes of product quality problems, improve product production process and production process, automatic detection and automatic identification. , automatic judgment, automatic sorting function. Automatically judge good and bad products, automatically sort good/bad products, and solve the traditional detection method because it takes a long time to waste on the loading tray and feeding, which leads to the problem that the actual overall inspection capacity is difficult to improve. The test results have stability, correctness and consistency. The image has excellent definition, automatic programming detection, automatic software detection and analysis, and excellent practicability.

X-ray non-destructive testing is a method of detecting internal structural anomalies or defects of a material by a physical method without impairing or affecting the performance of the object to be inspected without damaging the internal organization of the object to be inspected. Improve inspection speed and accuracy, save labor costs and improve product quality. X-ray non-destructive testing is an indispensable and effective tool for industrial development. The current development trend and urgent need for non-destructive testing equipment are faster, more accurate and more economical, which is determined by the current level of industrial manufacturing development.

National Service Hotline

ELT Technology Co., Ltd. All rights reserved

Address: 3rd Floor, Building B, Building 3, Building 2, Guangshen Road, Chaogang Town, Songgang Town, Bao'an District, Shenzhen, China.

Tel: 0755-29411968

Fax: 0755-27330185

E-mail :elt@elt-usa.com

Website: Http://m.szcyprint.com

Wechat Public Number

Mobile website